Product Description

Dia 1.20mm 1.60mm 2.40mm AWS A5.14 Inconel 718 ERNiFeCr-2 ENiFeCr-2

MIG Welding wire TIG Welding Rod

Inconel 718 filler metal ERNiFeCr-2 wire is used for the gas metal

arc and gas tungsten arc welding of alloys X-750 and 718. Alloy 718

is and age-hardenable alloy with excellent strength to 1200°F

(650°C). The alloy is used extensively in gas turbine components

and gas turbine repairs. In addition, the alloy can be used for

cladding and overlay of parts in the oil and gas industry. The

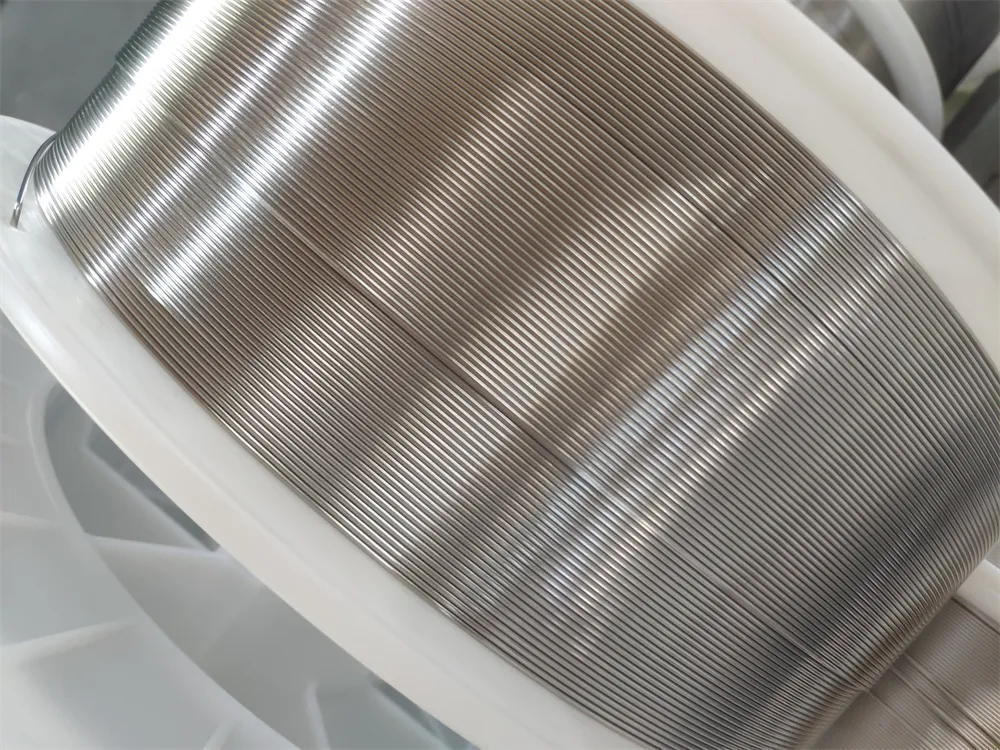

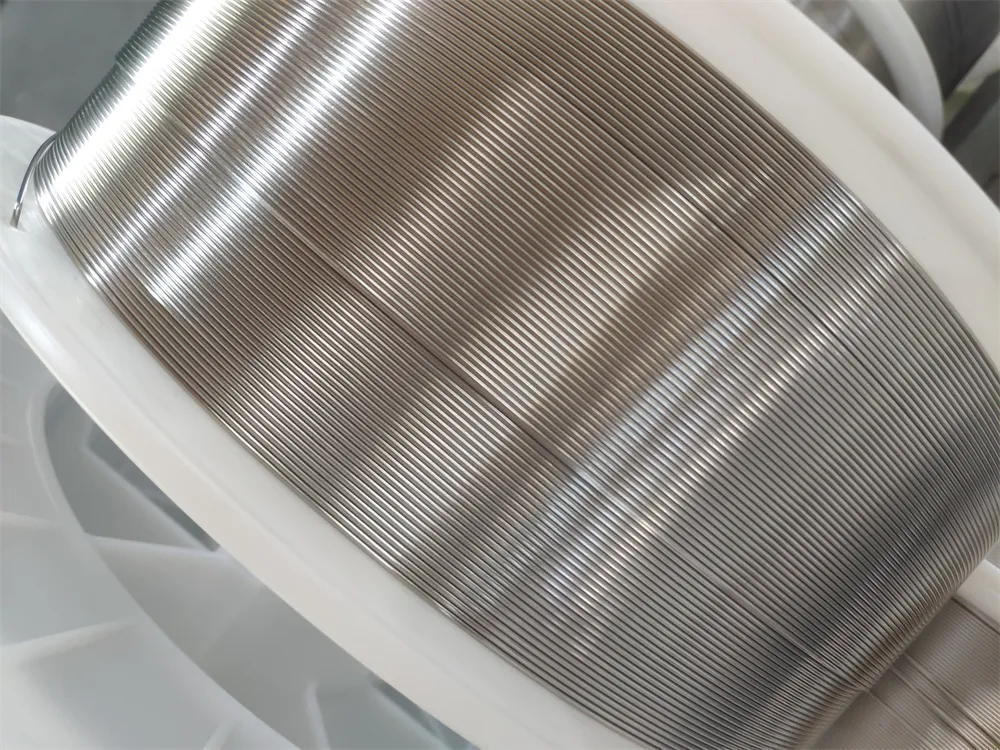

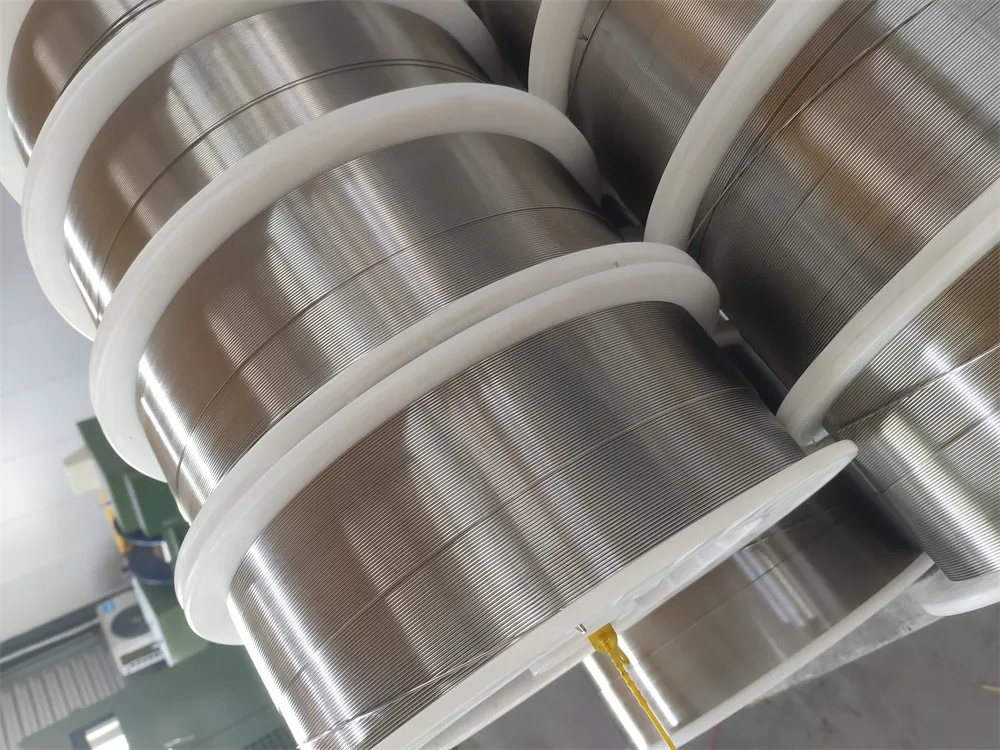

Inconel 718 filler metal finish on the spooled wire promotes smooth

feeding through welding equipment and reduced tip wear in contact

tips.

Specifications:

AWS A5.14 ERNiFeCr-2 UNS N07718

ASME-SFA-5.14 ERNiFeCr-2 AMS 5832

Standard: AWS A5.14 EN18274 ,ASME II, SFA-5.14, ERNiCrMo-3

Size:0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM

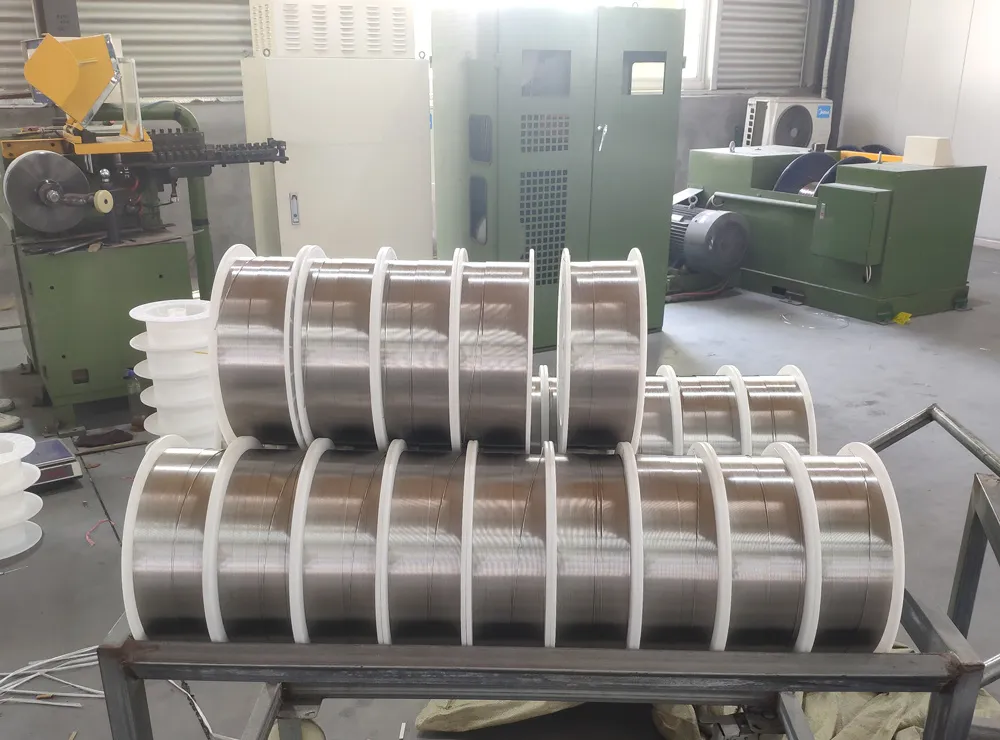

Form:MIG(15kg/spool), TIG(5kg/box)

Weling series:ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1

| Type | Standard | Manin chemcial composition % | Typical application |

| Nickel welding wire | A5.14 ERNi-1 | Ni ≥ 93 Ti3 Al1 Cr-- Mo-- | ERNi-1 is used for GMAW, GTAW and ASAW welding of Nickel 200 and

201, joining these alloys to stainless and carbon steels, and other

nickel and copper-nickel base metals. Also used for overlaying

steel. |

| NiCuwelding wire | A5.14 ERNiCu-7 | Ni 65 Cr-- Mo-- Ti2 Other: Cu | ERNiCu-7 is a copper-nickel alloy base wire for GMAW and GTAW

welding of Monel alloys 400 and 404. Also used for overlaying steel

after first applying Layer of 610 nickel. |

| CuNi welding wire | A5.7 ERCuNi | Ni 30 Cr-- Mo-- Other: Cu | ERCuNi is used for gas metal and gas tungsten arc welding. Can also

be used by oxy-fuel welding of 70/30, 80/20, and 90/10 copper

nickel alloys. A barrier layer of nickel alloy 610 is recommended

prior to overlaying steel with GMAW weld process. |

| NiCr welding wire | A5.14 ERNiCrFe-3 | Ni≥ 67 Cr 20 Mo--- Mn3 Nb2.5 Fe2 | Type ENiCrFe-3 electrodes are used for welding of

nickel-chromium-iron alloys to themselves and for dissimilar

welding between nickel-chromium-iron alloys and steels or stainless

steels. |

| A5.14 ERNiCrFe-7 | Ni: Rest Cr 30 Fe 9 | Type ERNiCrFe-7 is used for gas-tungsten-arc and gas-metal-arc

welding of INCONEL 690. |

| NiCrMo welding wire | A5.14 ERNiCrMo-3 | Ni≥ 58 Cr 21 Mo 9 Nb3.5 Fe ≤1.0 | ERNiCrMo-3 is used primarily for gas tungsten and gas metal arc and

matching composition base metals. It is also used for welding

Inconel 601 and Incoloy 800. It can be used to weld dissimilar

metal combinations such as steel, stainless steel, Inconel and

Incoloy alloys. |

| A5.14 ERNiCrMo-4 | Ni Rest Cr 16 Mo 16 W3.7 | ERNiCrMo-4 is used for welding nickel-chromium-molybdenum base

materials to itself, steel and other nickel base alloys and for

cladding steel. |

| A5.14 ERNiCrMo-10 | Ni Rest Cr 21 Mo 14 W3.2 Fe 2.5 | ERNiCrMo-10 is used for welding nickel-chromium-molybdenum base

materials to themselves, steel and other nickel base alloys, and

for cladding steels. Can be used to weld duplex, super duplex

stainless steels. |

| A5.14 ERNiCrMo-14 | Ni Rest Cr 21 Mo 16 W3.7 | ERNiCrMo-14 is used for gas-tungsten-arc and gas-metal-arc welding

of duplex, super-duplex and super-austenitic stainless steels, as

well as nickel alloys such as UNS N06059 and N06022, INCONEL alloy

C-276, and INCONEL alloys 22, 625, and 686. |

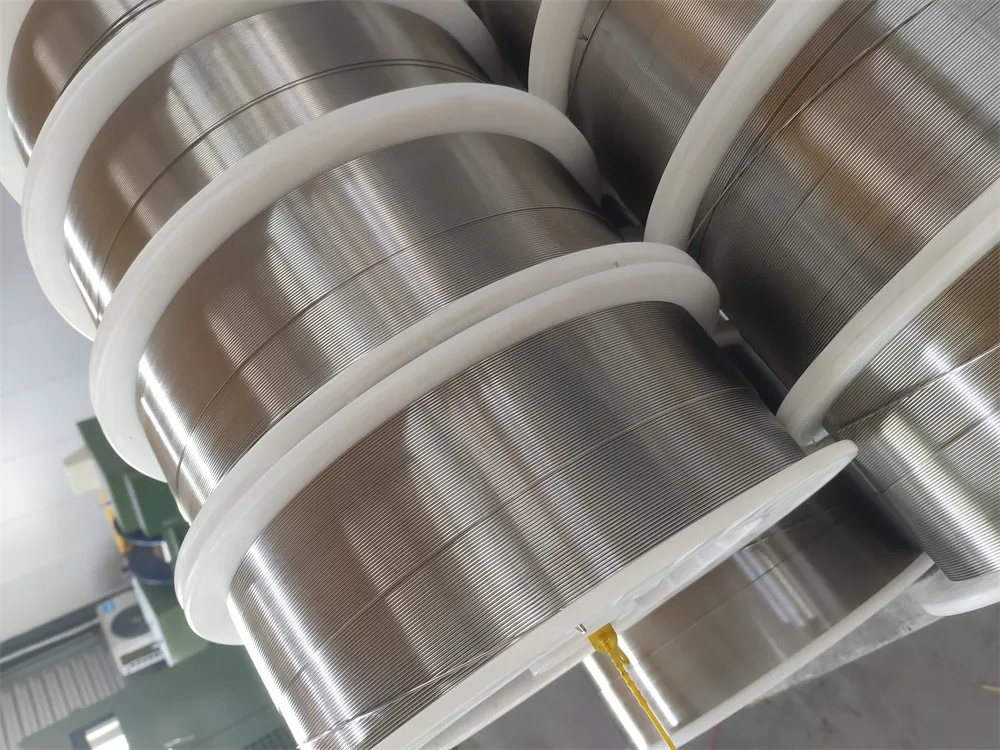

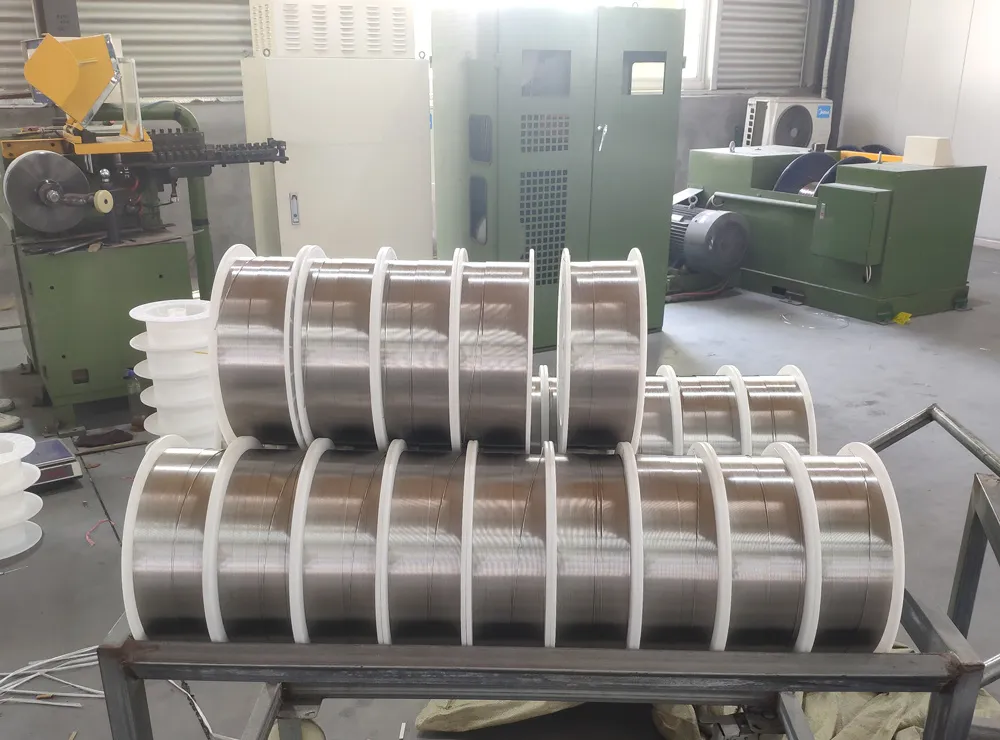

Detailed Photos